Kit Solution’s bushings for rod are essential to maintaining the integrity of hydraulic cylinders, effectively preventing fluid leakage. Mounted inside the guide sleeve, they operate in opposition to the rod itself, ensuring optimal sealing. Their function consists of blocking the flow towards the outside, thereby preserving the cylinder’s efficiency and preventing any compromise of its performance.

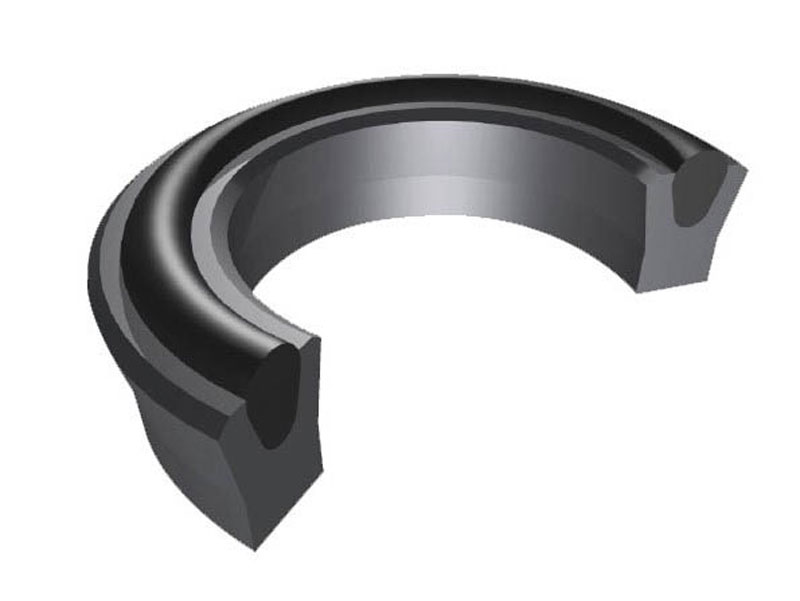

TSE/AI

The TSE seal is recommended for rod applications within hydraulic cylinders. The external sleeve version (TSE/AI) is suitable for piston seals with simple action. It is manufactured as a single component by the vulcanization of two materials: rubber fabric as an anti-extrusion element and NBR as a sealing element.

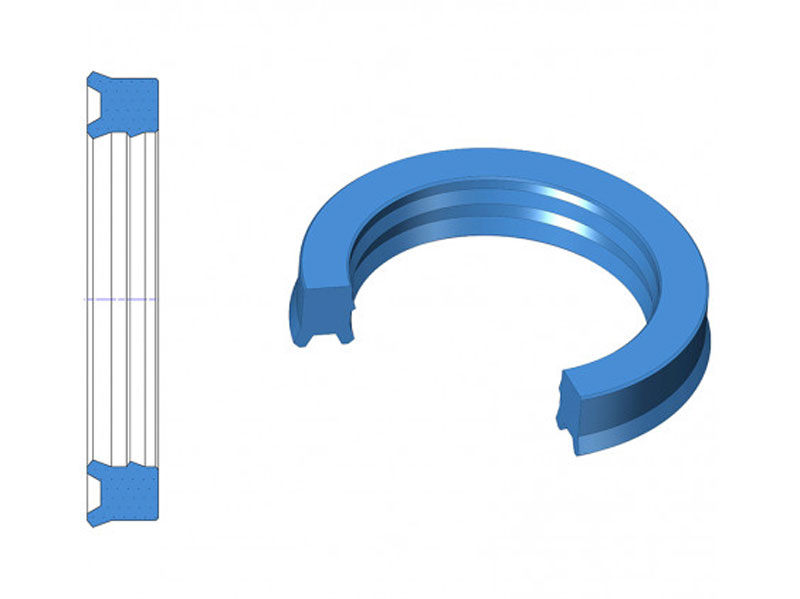

PSE PSE/K

The PSE is an effective seal for rod applications. Designed with a profile suitable for cases where hydraulic equipment is subjected to strong vibrations, impacts, and high pressure, the PSE/K seal element features a specially designed profile for use in mine field support applications. Another option beyond the above versions is the ability to produce seals using special materials for challenging working conditions.

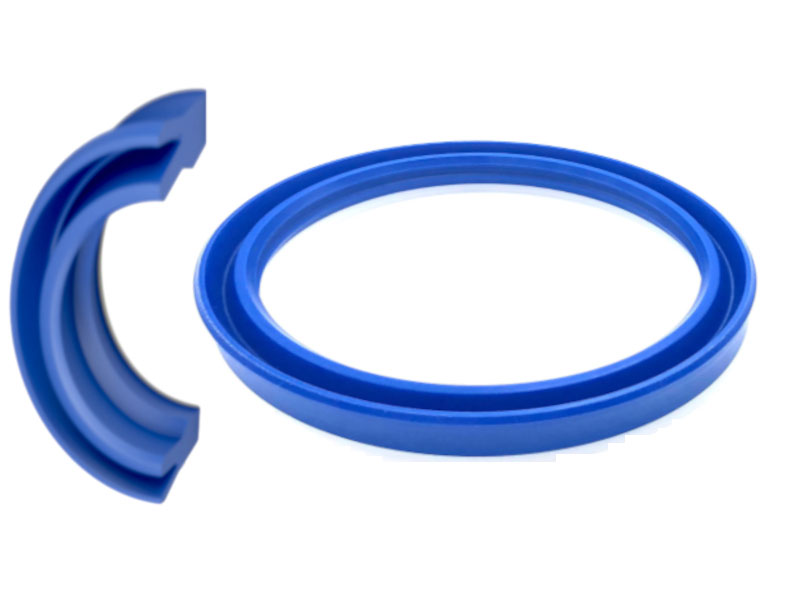

TTS/L

The seal design enables the achievement of high performance levels necessary for operation within the hydraulic cylinder under varying application conditions. The TTS/L version is a double-lipped rod seal designed for applications where high friction is encountered, such as telescopic cylinders.

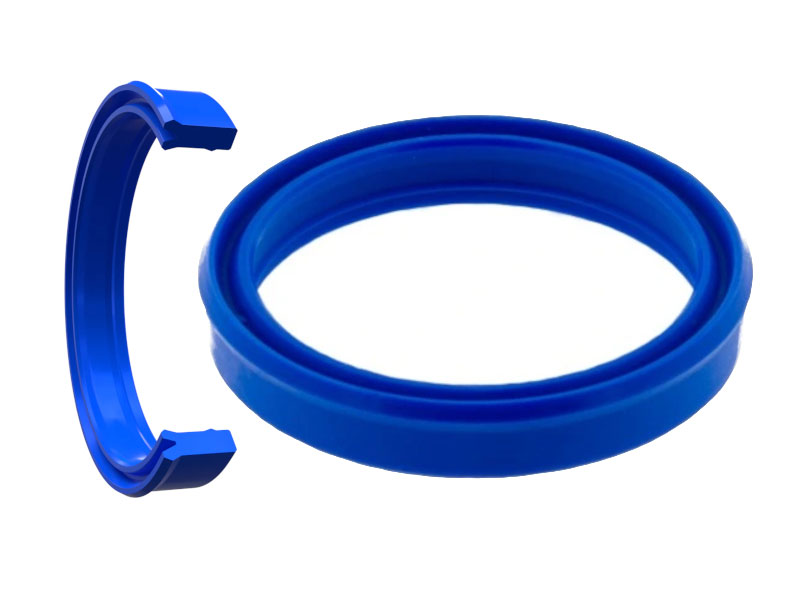

TTI/L

The simple TTI rod seal is an efficient sealing element made from polyurethane “Tecnolan”. Designed with an asymmetrical transverse section that provides optimal sealing performance. The TTI/L version features a secondary lip that ensures excellent performance under challenging operating conditions.

TTH/AI

The TTHs, designed for rod application, are made from polyurethane “Tecnolan” and feature characteristics such as high elasticity, low deformation, and excellent abrasion resistance. The TTH seal boasts exceptional quality performance under conditions where high pressure, extrusion, and mechanical coupling occur over a wide range.

TTX. TTX+S

Developed for demanding working conditions, the TTX, made from polyurethane “Tecnolan”, provides the necessary characteristics such as high elasticity, low deformation, and abrasion resistance. The presence of a secondary lip on the dynamic seal, which is subjected to radial load, ensures complete sealing even under high pressure conditions, extreme extrusion factors, and wide range of mechanical coupling.